Article

How Are Modular Homes Made?

Design inspiration

Modular construction

February 09, 2024

Written by

Alana McNab

Are you thinking about how to build your new home, but finding it hard to decide which construction method to choose? We understand it's a big decision, and we're here to help make it easier for you.

Chances are, you're considering alternatives to traditional construction methods due to their complexities and challenges. Well, modular homes might just be the answer you're looking for, offering a range of benefits that could suit your needs perfectly.

In this blog, we'll walk you through how modular homes are built and provide you with the knowledge and confidence to navigate this construction approach with ease and certainty.

What is a modular home?

Built primarily in a manufacturing facility, modular homes are built in sections to around 90-95% completion off-site. These modules are then transported and assembled on the building site. Once installed on the foundations and connected to the services, modular homes are permanent dwellings just like traditional built homes.

The modular building process

After the design and paperwork are complete, the modular building process begins. This is usually divided into the following key stages:

1. The frame stage

The first step of modular construction is to build the house frame. Most modular companies use steel for the base frame as it is strong, reliable, and able to withstand transport on a truck. During the framing stage, the carpenters will install the particle board flooring, build the timber wall and roof structure, and brace the frame. When this work is complete, a Building Surveyor will inspect the frame.

A key benefit to building homes in a factory environment is that it significantly reduces waste and the environmental impact on site. This is facilitated by the ability to store excess materials for future use, rather than disposing of them. Furthermore, the trades constructing the homes primarily work within the factory environment until the home is transported to the site, minimising disturbances and the environmental impact on-site.

Pictured here is our two-storey, custom designed Olinda project whilst it was under construction at our factory location. Throughout this blog you will be able to view the building journey of this magnificent modular home.

2. The lock-up stage

The next step is to add all the exterior features onto the prefabricated frame so that it is a weather tight and secure home. This includes the roofing, guttering, external cladding, windows, doors, and decking. During this stage, the electrical and plumbing contractors will also run their wiring.

Since this stage takes place in a controlled environment, the contractors can work quickly and without delay. It also allows for smoother workflows and more refined collaboration between different subcontractors.

3. The fixing stage

During the fixing stage, all the surfaces and fixtures are added, such as carpentry, cabinet making, plastering, tiling, plumbing, and electrical. The last step of the fixing stage is to install the flooring, at which point, the home is ready for delivery.

4. Site preparation

Before the modular home is scheduled for delivery, all the site preparation needs to be completed, including excavation, foundations, and retaining walls. This way, your site will be ready for installation on delivery day.

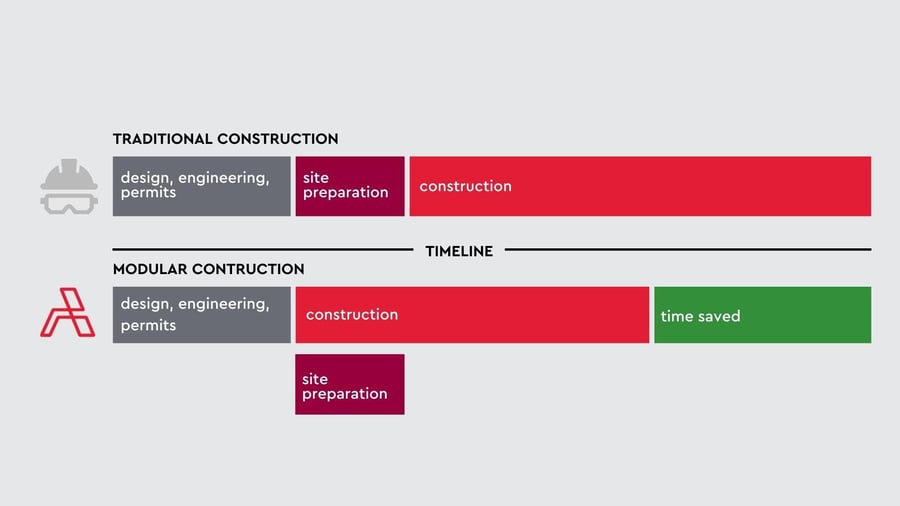

One of the key benefits of modular construction is that you can complete this step at the same time as the factory construction phase, resulting in faster timelines so you can move into your new home sooner.

5. Delivery and installation

When the house and building site are ready, the house will be loaded onto a truck and delivered to its location. Once it arrives, the modules are reassembled and made into one cohesive unit. At Anchor Homes, this process takes as little as one to three days, depending on your location and the size of your project.

The remaining site work can then be completed, including any of the following finishing touches:

- Plastering.

- Painting.

- Sub-floor cladding.

- Commission of the electrical and plumbing infrastructure.

- Stairs and balustrade.

- Connection to site services.

- Construction of the garage or carport (if included).

At this point, the Building Surveyor will complete a final inspection before issuing a Certificate of Occupancy.

Modular Homes Melbourne Metro, Regional Victoria and Southern NSW

At Anchor Homes, we pride ourselves on designing and building reliable, high-quality modular homes. We also know the value of a seamless building experience and always strive to provide you with exceptional customer service.

When building a home with us, you’ll gain access to our experienced team of designers, builders, and project consultants who will help bring your vision to life.

To simplify the process for you, we’ve broken it down into the following 10 steps:

- Complimentary consultation

- Project proposal

- Design and site engineering

- Council permits

- Specification selection and documentation

- Contract

- Building permit

- Construction

- Delivery and site work

- Handover

Over to you

The popularity of modular homes is rapidly increasing worldwide as individuals now recognise that they are the ideal solution for building high-quality homes quickly, efficiently and sustainably.

At Anchor Homes, we stand ready to guide you through every phase of your modular home project, offering expertise, reliability, and exceptional customer service. Whether you're considering a pre-designed home, minor customisations, or a completely custom design, our experienced team is dedicated to bringing your vision to life.

If you’re keen to kickstart your new modular home project, we’d love to help. Talk to our expert team or book a time to visit our display homes and take the first step towards making your dream home happen!

.png?width=776&height=498&name=Floorplan%20Coming%20Soon%20(33).png)

.png)